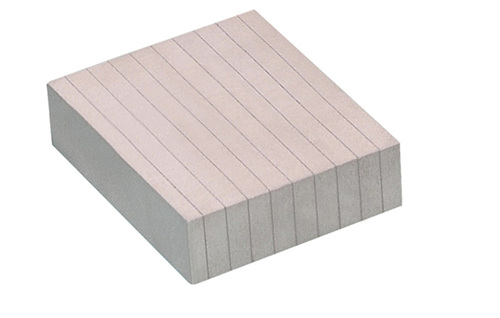

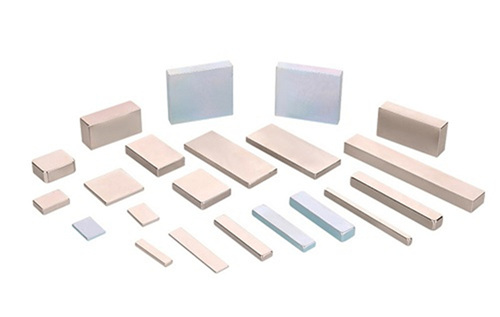

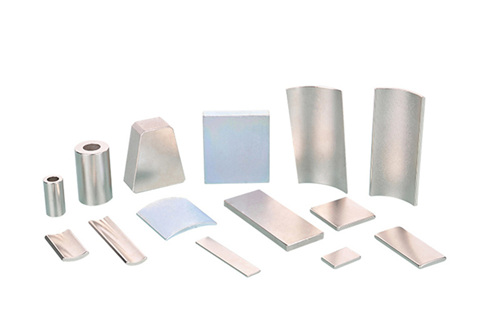

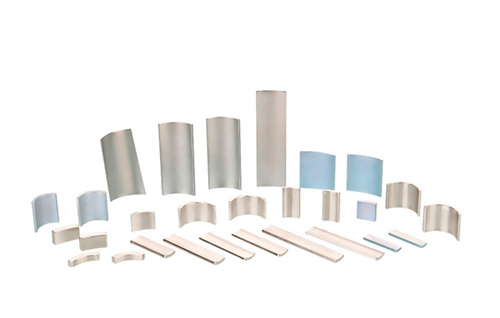

Samarium cobalt (SmCo) and neodymium (NdFeB) magnets are two types of rare earth magnets known for their strong magnetic properties.

Magnetic Strength: Neodymium magnets are generally stronger than samarium cobalt magnets. Neodymium magnets can have magnetic energy products up to around 52 MGOe (MegaGauss Oersted) whereas samarium cobalt magnets typically range from 20 to 35 MGOe.

Temperature Stability: Samarium cobalt magnets have better temperature stability compared to neodymium magnets. They can operate at higher temperatures without losing their magnetic properties. Neodymium magnets start to lose strength at temperatures above 80°C (176°F), while samarium cobalt magnets can operate at temperatures up to 250°C (482°F) without significant loss of performance.

Corrosion Resistance: Samarium cobalt magnets have better corrosion resistance compared to neodymium magnets. Neodymium magnets are prone to corrosion in humid or corrosive environments unless they are coated with a protective layer.

Cost: Neodymium magnets are generally more cost-effective than samarium cobalt magnets due to the availability of raw materials and manufacturing processes.

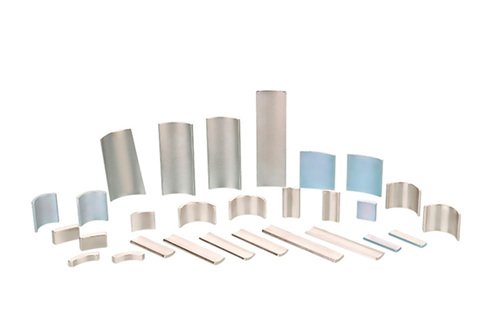

Applications: Both types of magnets find applications in various industries such as electronics, automotive, aerospace, medical devices, and renewable energy. Neodymium magnets are often used in consumer electronics like headphones, speakers, and hard drives due to their high strength-to-weight ratio. Samarium cobalt magnets are preferred in applications where high temperature stability and corrosion resistance are critical, such as in motors, sensors, and aerospace applications.